There's little more frustrating in logistics, retail, or inventory management than the failed beep of a barcode scanner. An unscannable barcode halts workflows, introduces errors, and impacts efficiency. While scanner issues or printing problems can be culprits, often the root cause of why your barcode won't scan lies in how it was created. Using a barcode generator is convenient, but simple mistakes during the process can lead to significant barcode scanning issues.

This guide highlights the five most common barcode generator errors and provides actionable solutions for consistently scannable, reliable, and effective barcodes.

Mistake #1: Choosing the Wrong Barcode Type (Symbology)

Different industries and applications rely on specific barcode languages, known as symbologies. Using the wrong one is a primary reason for scan failures.

Not all barcodes are interchangeable. Retail typically uses UPC (Universal Product Code) or EAN (European Article Number) for consumer products. Logistics and internal tracking often favor Code 128 or Code 39 due to their ability to encode alphanumeric data. QR Codes handle larger data sets like URLs or contact info. Generating a barcode using a symbology inappropriate for its intended use or data type (e.g., putting letters into a numeric-only EAN code) guarantees it won't work.

Common Causes

● Accepting the generator's default symbology without verification.

● Lack of understanding regarding application-specific requirements (e.g., GS1 standards for retail).

● Inputting incompatible data (alphanumeric characters into a numeric-only symbology).

Best Practices & Fixes

● Research: Identify the correct barcode symbology required for your specific application before generating.

● Verify Data: Ensure the data you input matches the chosen symbology's character set capabilities.

● Use Guidance: Leverage generator tools that offer suggestions based on common use cases.

Mistake #2: Insufficient Quiet Zone (Margins)

The blank space surrounding a barcode is just as critical as the bars themselves.

This mandatory blank area before the start character and after the stop character is called the "Quiet Zone." Scanners require this clear space to recognize where the barcode begins and ends, differentiating it from surrounding elements. Insufficient barcode margins mean the scanner cannot reliably detect the full code.

Common Causes

● Manually cropping the generated barcode image too close to the bars.

● Placing text, logos, or other graphic elements directly adjacent to the barcode.

● Ignoring the generator's built-in padding or margin settings.

Best Practices & Fixes

● Respect the Space: Ensure a clear space on all sides. A general rule is the Quiet Zone should be at least 10 times the width of the narrowest bar/space (the X-dimension), or roughly 0.25 inches (6.4mm), whichever is greater.

● Use Generator Settings: Utilize the barcode generator's options for automatically including standard quiet zones.

● Design Carefully: Keep other design elements well away from the barcode area.

Mistake #3: Incorrect Size or Density (X-Dimension Issues)

Size matters significantly in barcode scannability. Generating a barcode that's too small or too dense can render it unreadable.

The "X-dimension" refers to the width of the narrowest element (bar or space) in the barcode. If this dimension is too small (high density), many scanners, especially those used at a distance, may not have the resolution to distinguish the individual bars and spaces. Conversely, excessively large barcodes might not fit within the scanner's field of view. Achieving the right barcode size is crucial.

Common Causes

● Shrinking a generated barcode image excessively to fit a small label space.

● Attempting to encode very long data strings into linear barcodes, forcing high density.

● Not considering the scanning environment (distance, scanner type) when choosing size/density.

Best Practices & Fixes

● Adhere to Standards: Refer to industry standards (like GS1 General Specifications) for minimum X-dimension and size requirements if applicable.

● Test Thoroughly: Print test labels and verify scannability with the actual scanners and distances intended for use.

● Optimize Data: Keep encoded data concise where possible, or consider 2D codes like QR or Data Matrix for longer strings.

● Generate Appropriately: Aim for a minimum X-dimension suitable for your scanning equipment (e.g., 10-15 mils for general use).

Mistake #4: Poor Contrast or Wrong Colors

Barcode scanners rely on contrast, not necessarily color perception as humans see it.

Scanners work by detecting the difference in reflectance between the dark bars and the light spaces. High barcode contrast (ideally black bars on a white background) is essential. Low contrast (e.g., dark grey bars on light grey background) or certain color combinations (like red bars on white, as many laser scanners use red light which reflects off red) make it difficult or impossible for the scanner to differentiate the pattern.

Common Causes

● Using "creative" color combinations for branding purposes.

● Printing barcodes directly onto colored or patterned packaging/labels.

● Ink bleed (print gain) during printing, reducing the width of white spaces.

Best Practices & Fixes

● Stick to Basics: The gold standard is black bars on a white background. Dark blue or dark green on white can also work.

● Avoid Problematic Colors: Never use red, orange, or yellow bars (they reflect red laser light). Avoid printing on highly reflective or dark backgrounds.

● Ensure Print Quality: Use quality printing methods to minimize ink spread and maintain clear space definition. Check barcode print quality regularly.

Mistake #5: Low Resolution or Incorrect Format

Generating a perfect barcode digitally means little if it's exported improperly for printing.

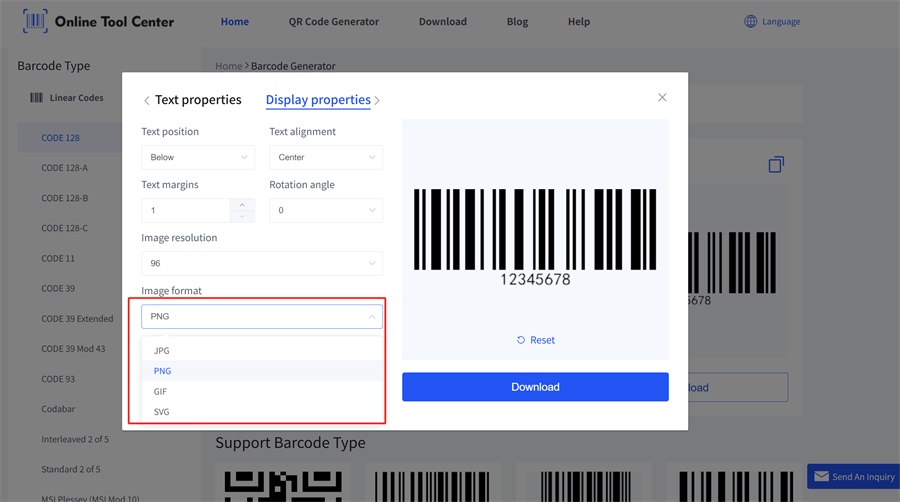

Exporting a barcode as a low-resolution raster image (like a low-quality JPG or small PNG) can cause pixelation and blurred edges when printed. This distortion makes the bars and spaces indistinct, leading to barcode scan failures. The chosen barcode image format and resolution are critical.

Common Causes

● Saving barcodes in lossy formats like JPG, which introduce compression artifacts.

● Exporting at a low DPI (Dots Per Inch) unsuitable for the final print size.

● Using a low-resolution image and scaling it up, causing severe blurriness.

Best Practices & Fixes

● Prioritize Vector: Whenever possible, export barcodes in vector formats like SVG or EPS. Vectors scale infinitely without losing quality, ensuring sharp lines at any print size — ideal for professional printing.

● Avoid JPG: Do not use JPG format for barcodes due to its lossy compression. Stick to PNG barcode or TIFF for high-quality raster output.

Beyond the Generator: Other Potential Scan Issues

While generator mistakes are common, remember other factors can cause scanning problems:

● Printer Quality: Low ink/toner, smudging, inconsistent printing.

● Label Issues: Damaged, wrinkled, curved, or highly reflective label surfaces.

● Scanner Problems: Incorrect settings, wrong scanner type for the symbology, dirt on the lens, excessive scanning distance or angle.

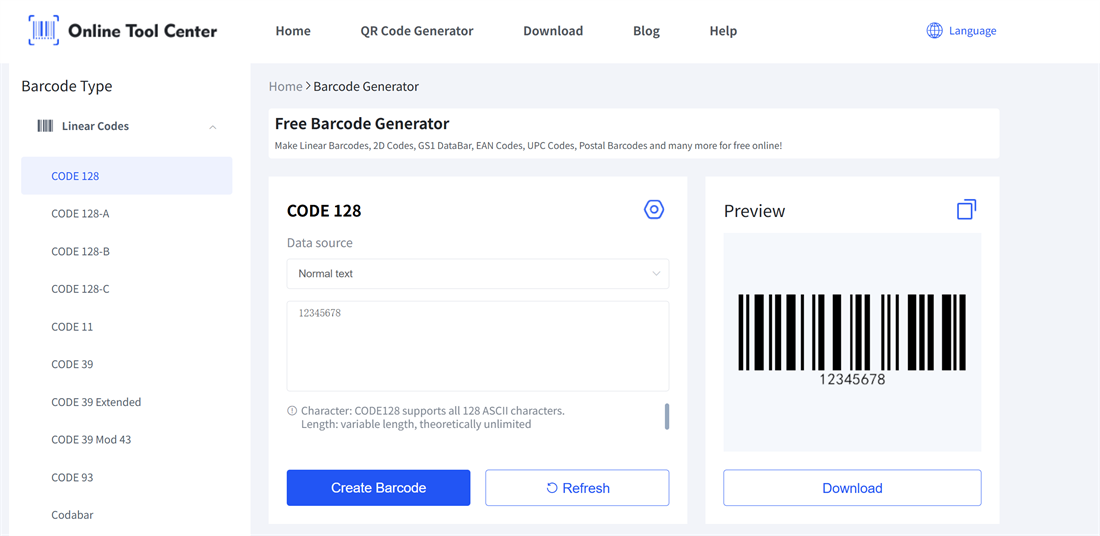

How Our Barcode Generator Helps You Succeed

Understanding these pitfalls is the first step. The next is using a tool to help you avoid them. Our online barcode generator incorporates features specifically aimed at preventing these common barcode scanning issues:

● Clear Symbology Selection: Guidance on common barcode types and their uses.

● Size & Preview: Real-time previews and clear settings help you achieve the right barcode size.

● High-Contrast Defaults: Optimized black-and-white output is standard.

● Quality Export Options: Support for vector barcode formats (like SVG) and high-resolution PNG barcode ensures optimal barcode print quality.

A barcode won't scan scenario is often preventable. By avoiding these five common barcode generator mistakes — choosing the right symbology, ensuring adequate quiet zones, optimizing size and density, maintaining high contrast, and exporting in the correct format and resolution — you dramatically increase your chances of success.

Paying attention during the generation process saves significant time and resources down the line. Ready to create reliable, scannable barcodes without the guesswork?